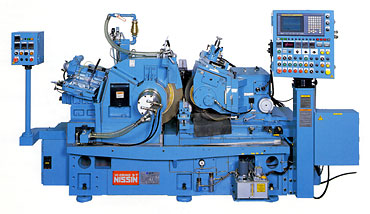

HI-GRIND3-T

Product features

1. Both GW spindle and RW spindle are supported at both ends by Hydrostatic Bearings; very rigid & reliable centerless grinder.

2. CNC servo motor is applied to RW table infeed/compensation unit for easy operation.

3. V-flat plain Guideway is applied to RW table for high rigidity.

4. Hydrostatic Bearings offer advantages as follows;

a)No frictional drag

b)No friction and low temperature rize

c)Constant rotating accuracy

d)High film stiffness independent on the number of rotation.

5. Combination of Servo Motor and Ball Screw gives precise and fine feed/compensation.

Mechanical specifications

You can scroll by flicking.| Capacity | Work Diameter | Φ120mm |

|---|---|---|

| Max. Infeed Length | 300mm |

|

| GW | Dimensions | Φ610×305×Φ304.8mm |

| Surface Speed | 2,600m/min or 2,000m/min | |

| Motor Capacity | 22kW(※37kW) ※OPTION |

|

| Bearings | Hydrostatic oil Bearing, supported at both ends | |

| RW | Dimensions | Φ355×305×Φ177.8mm |

| RPM | 1~300r/min(60Hz) |

|

| Motor Capacity | Servo Motor Drive | |

| Bearings | Hydrostatic oil Bearing, supported at both ends | |

| GW Dresser | Traverse | Hydraulic Cylinder |

| Infeed | Micro Handle(0.02mm/div) | |

| RW Dresser | Traverse | Hydraulic Cylinder |

| Infeed | Micro Handle(0.02mm/div) | |

| Infeed Mechanism | RW Table Slide | V-flat plain Guideway |

| Drive Method | Servo Motor Drive | |

| Minimum Setting Unit | 0.1μm |

|

| Minimum for guarantee | 1μm | |

| Weight | 6,500kg |

|