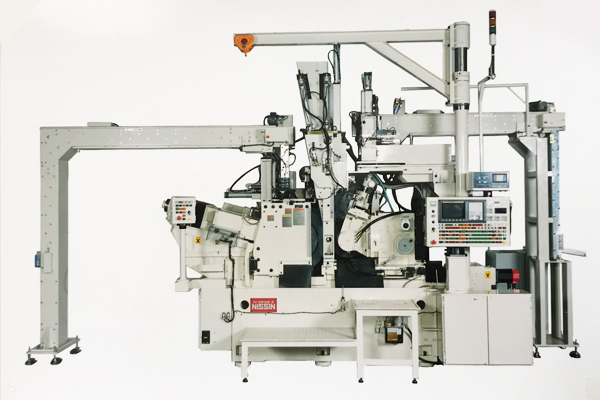

Centerless Grinding Machine

Manufacturer with

the longest history in Japan

NISSIN has the longest history of centerless grinder manufacturing in Japan. In 1940, first centerless grinder was developed by us in Japan, and the production is continuing up to the present time.

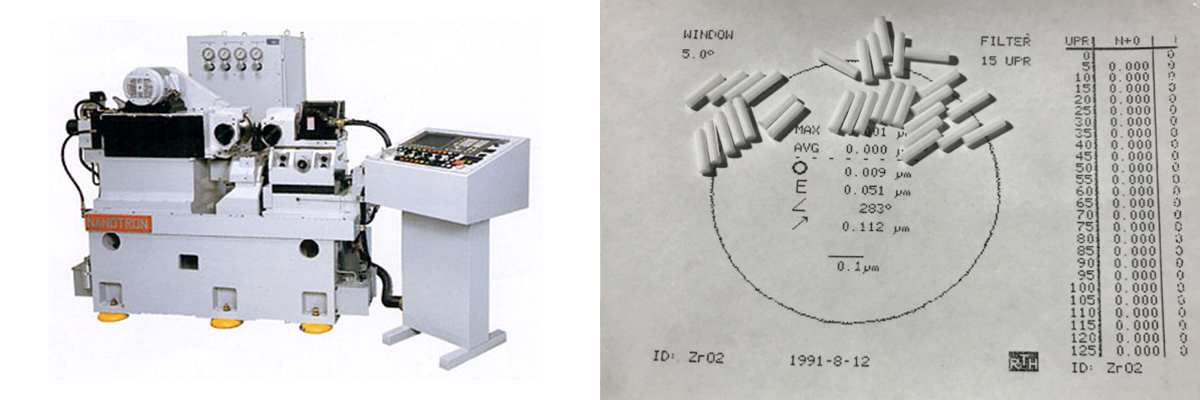

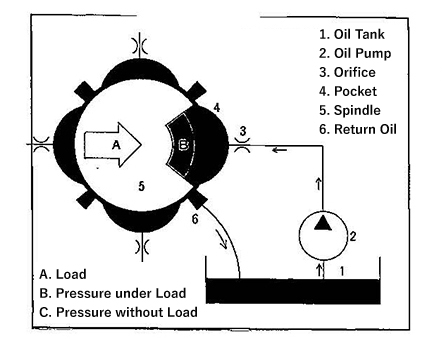

In 1970, HI-GRIND 2 model with Hydrostatic Bearings , main feature of NISSIN

centerless grinders at present, was developed.

In 2010, “Best Technical Award” is given to this model by the “Association to Recognize Historic Valuable Machine Tool in Japan”.

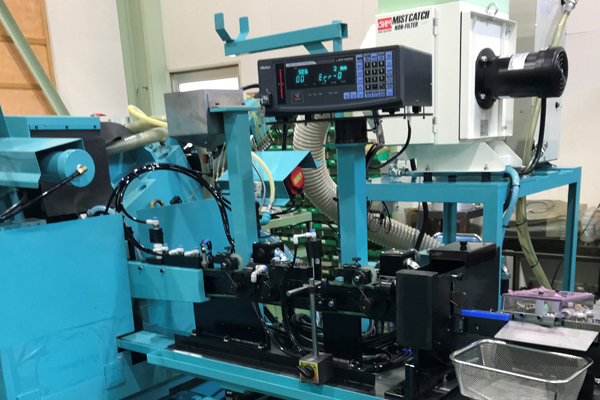

Small type ultra precision model NANOTRON capable of nano meter range accuracy

was developed in 1987 and presented on the technical conference in U.S.A.(1993-ASPE).

In 2017, presentation was made on ultra precision centerless grinder UG-150-II model in Okinawa,Japan (2017-ISAAT).