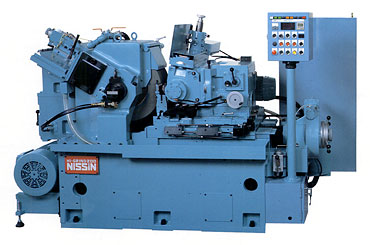

HI-GRIND200

Product features

1. For grinding wheel side, stationary spindle structure with high rigidity and accuracy is applied.

2. Using both support stationary spindle structure, 510Փx205x228.6Փ wheel is used in a small floor space.

3. Hydrostatic guide way is used for infeed and compensation slide and keeps accurate compensation for a long period.

4. Various optional devices, CNC dresser, Rotary dresser, CNC infeed device, are available.

Mechanical specifications

You can scroll by flicking.| Capacity | Work Diameter | ~Φ40mm |

|---|---|---|

| GW | Dimensions | Փ510x205xՓ228.6mm |

| Surface Speed | 2,700m/min |

|

| Motor Capacity | 11kW(4P) |

|

| Bearings | Stationary Spindle(Hydrostatic Oil Bearing) | |

| RW | Dimensions | Φ255×205×Φ127mm |

| RPM | 18~200r/min(60Hz) |

|

| Motor Capacity | 0.75kW(4/8P) |

|

| Bearings | Hydrostatic Oil Bearing | |

| Tilt angle | +5°~ -3° |

|

| GW Dresser | Traverse | Hydraulic Cylinder |

| Infeed | Micro Handle(0.02mm/div) | |

| RW Dresser | Traverse | Hydraulic Cylinder |

| Infeed | Micro Handle(0.02mm/div) | |

| Infeed Mechanism | Method | Ball Screw and Hydrostatic Guideway |

| Minimum Setting Unit | 0.5µm/push(Variable) | |

| Weight | 4,000kg | |