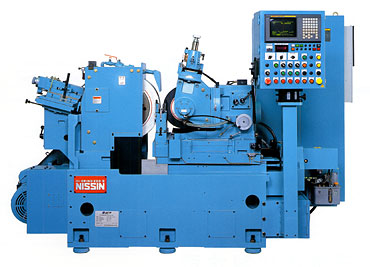

HI-GRIND200-II

Product features

1. Cost-effective machine with high accuracies, high efficiency and high productivity.

Hydrostatic bearings are applied to both wheel head.

2. Hydrostatic bearings offer advantages;

a)no abrasion

b)extremely low friction and low temperature rise

c)high oil film stiffness independent on the number of rotation

d)precise and constant rotating accuracy

3. Open sided support is applied to GW spindle for convenient changeover operation.

4. RW table is driven by CNC for consistent infeed cycle and high accuracies.

a)Beginners are able to make infeed cycle patterns by using easy to understand Macro Variables.

b)Reliable V and flat guideway is applied for RW table, which is based on long experiense,

rich achievements and veteran craftsmanship.

c)Mechanical compensation is available for thru-feed grinding. (Option)

Mechanical specifications

You can scroll by flicking.| Capacity | Work Diameter | ~Φ75mm |

|---|---|---|

| Max. Infeed Length | 200mm | |

| GW | Dimensions | Φ510×205×Φ304.8mm |

| Surface Speed | 2,700m/min | |

| Motor Capacity | 11kW | |

| Bearings | Hydrostatic oil Bearing | |

| RW | Dimensions | Φ330×205×Φ127mm |

| RPM | 18~236r/min(60Hz) | |

| Motor Capacity | 0.75kW | |

| Bearings | Hydrostatic oil Bearing | |

| GW Dresser | Traverse | Hydraulic Cylinder |

| Infeed | Micro Handle(20µm/div) | |

| RW Dresser | Traverse | Hydraulic Cylinder |

| Infeed | Micro Handle(20µm/div) | |

| Infeed Mechanism | RW lower Slide | Hydrostatic Guideway(V and flat) |

| Drive Method | AC servo motor |

|

| Minimum Setting Unit | 0.1μm | |

| Weight | 3,600kg | |