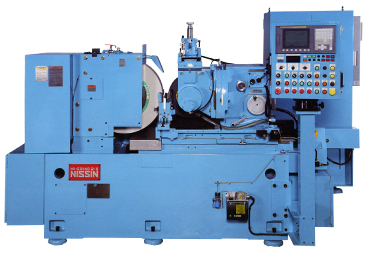

HI-GRIND2-III

Product features

1. Both spindles are supported by Hydrostatic Bearings, and V & flat slide with experienced scraping technology and turcite coating is

applied to RW lower slide.

2. CNC servo motor, which is standard accessories, is applied to RW lower slide drive for easier operation for size compensation.

3. Cost-effective machine with high accuracies, high efficiency.

a)Hydrostatic Bearings, applied to both wheel head, offer advantages; no abrasion , high oil film stiffness independent on the number

of rotation and precise & constant rotating accuracy.

b)V & flat slide realizes fine forward, backward compensation.

Mechanical specifications

You can scroll by flicking.| Capacity | Work Diameter | Φ2mm~Φ100mm |

|---|---|---|

| Max. Infeed Length | 200mm(※250mm) ※OPTION |

|

| GW | Dimensions | Φ610×205(※255)×Φ304.8mm ※OPTION |

| Surface Speed | 2,700m/min |

|

| Motor Capacity | 15kW(※22kW) ※OPTION |

|

| Bearings | Hydrostatic Oil Bearings |

|

| RW | Dimensions | Φ355×205(※255mm)×Φ177.8mm ※OPTION |

| RPM | 18~200r/min(60Hz) |

|

| Motor Capacity | 0.75kW |

|

| Bearings | Hydrostatic Oil Bearings |

|

| GW Dresser | Traverse Drive | Hydraulic Cylinder |

| Infeed Drive | Micro Handle(0.02mm/div) |

|

| RW Dresser | Traverse Drive | Hydraulic Cylinder |

| Infeed Drive | Micro Handle(0.02mm/div) |

|

| RW Table | RW Lower slide | V & Flat Slide With Turcite Coating |

| Drive Method | AC servo motor |

|

| Minimum Setting Unit | 0.1μm |

|

| Weight | 5,500kg |

|